GMP Clean Room Solution

Overview

GMP stand for Good Manufacture Practice guidelines have been developed by a variety or governmental and regulatory bodies for a variety of industries specially in pharmaceutical, medical, and food industries to ensure consumer and employee health and safety. We can provide customized solutions for customers to meet the requirements of hygienic quality in terms of clean room construction, raw materials, personnel, facilities and equipment, production process, packaging and transportation, quality control and other aspects in accordance with relevant national laws and regulations, and form a set of operational norms to help customers improve the hygienic environment and discover question which existing production process in time.

Application Scenes

Pharmaceutical Factory

Medical Apparatus Factory

Food Factory

Cosmetics Plant

Hospital Central Supply Room

Medical Apparatus Factory

Food Factory

Cosmetics Plant

Hospital Central Supply Room

Pharmaceutical Factory

Key Feature

By customizing solutions, cooperating with purifying air conditioning units and building materials conforming to GMP standards, we can provide customers with complete and reliable clean room production process plan, help customers meet the industry standards and requirements of the government and relevant units, and realize safe production operation.

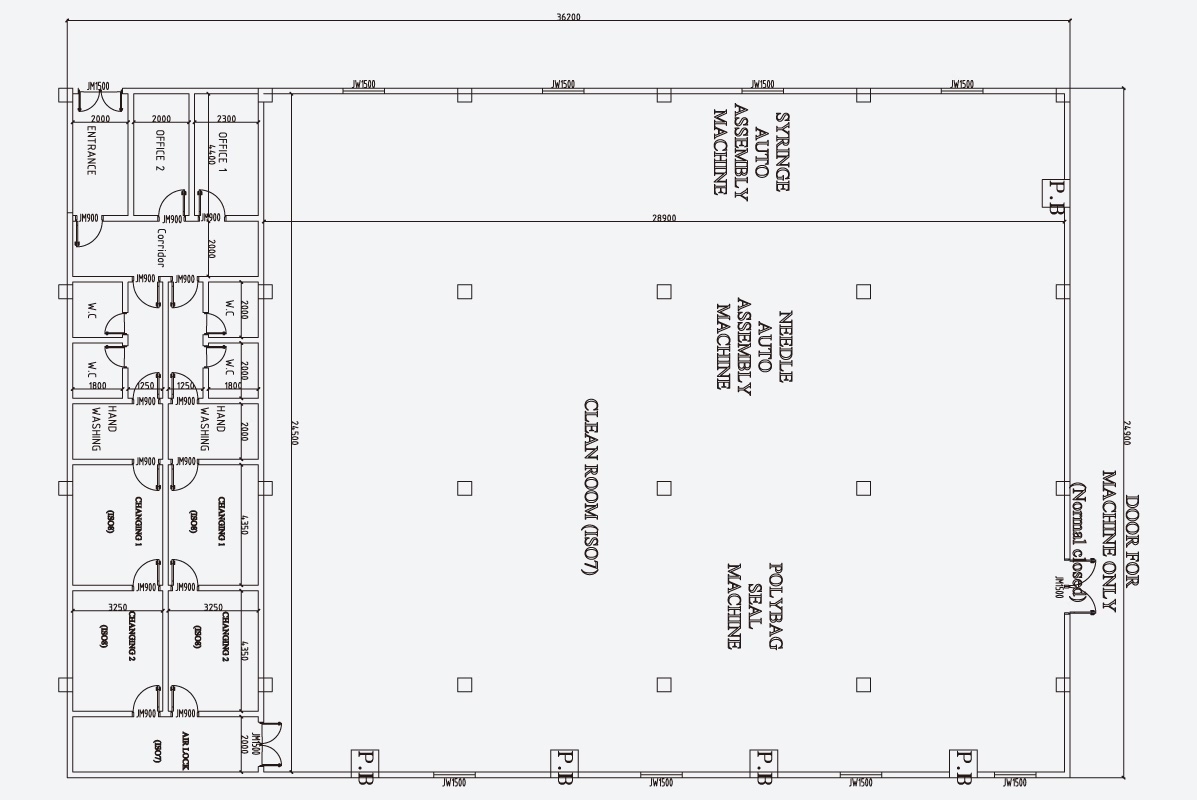

1. Strict floor layout process

2. Strict indoor environment requirements: decoration quality, air quality, cleanliness, temperature and humidity, aseptic environment, pressure gradient, noise, etc.

3. Some GMP workshops have low-humidity process production requirements, which require a rotary dehumidifier, which requires high energy consumption.

4. Strict production management process

Solution

We have our own factory and design, construction team, with 12 years of overseas project experience, can provide customers with customized, full process solutions for cleanroom engineering.

Characteristic:

Provide customized design, design drawings and corresponding HVAC equipment in full accordance with the actual situation of the client’s project site, so as to meet the indoor air environment requirements required by the clean room, and pass the inspection of the local third-party organization of the project

Advantages:

Our team has more than 10 years of experience, and has provided high-quality products for more than 150 countries and regions around the world. Moreover, we have our own overseas construction team, which can provide customers with one-stop EPC overall project packaging services, and solve all the needs of customers in the clean room project.

Benefits:

- Competitive price, because we have our own factory to provide clean room purification equipment.

- Fast response speed, because we have our own design team.

- Free and professional scheme design (when the client cooperates with our company in the unit or material construction of the clean room).

- Fast and professional construction and after-sales service, because we have our own overseas construction team